MTU Parts in China: A Comprehensive Guide

MTU is a renowned name in the field of high-speed diesel engines and propulsion systems, originating from Germany. The company specializes in manufacturing a wide range of products including engines, turbines, and drive systems. The significance of MTU parts cannot be overstated, especially considering the growing demand for durability and performance in today's industrial landscape. In this article, we will delve into the world of MTU parts in China, exploring their production, distribution, and role in the broader diesel engine and generator supply market.

Understanding MTU Parts

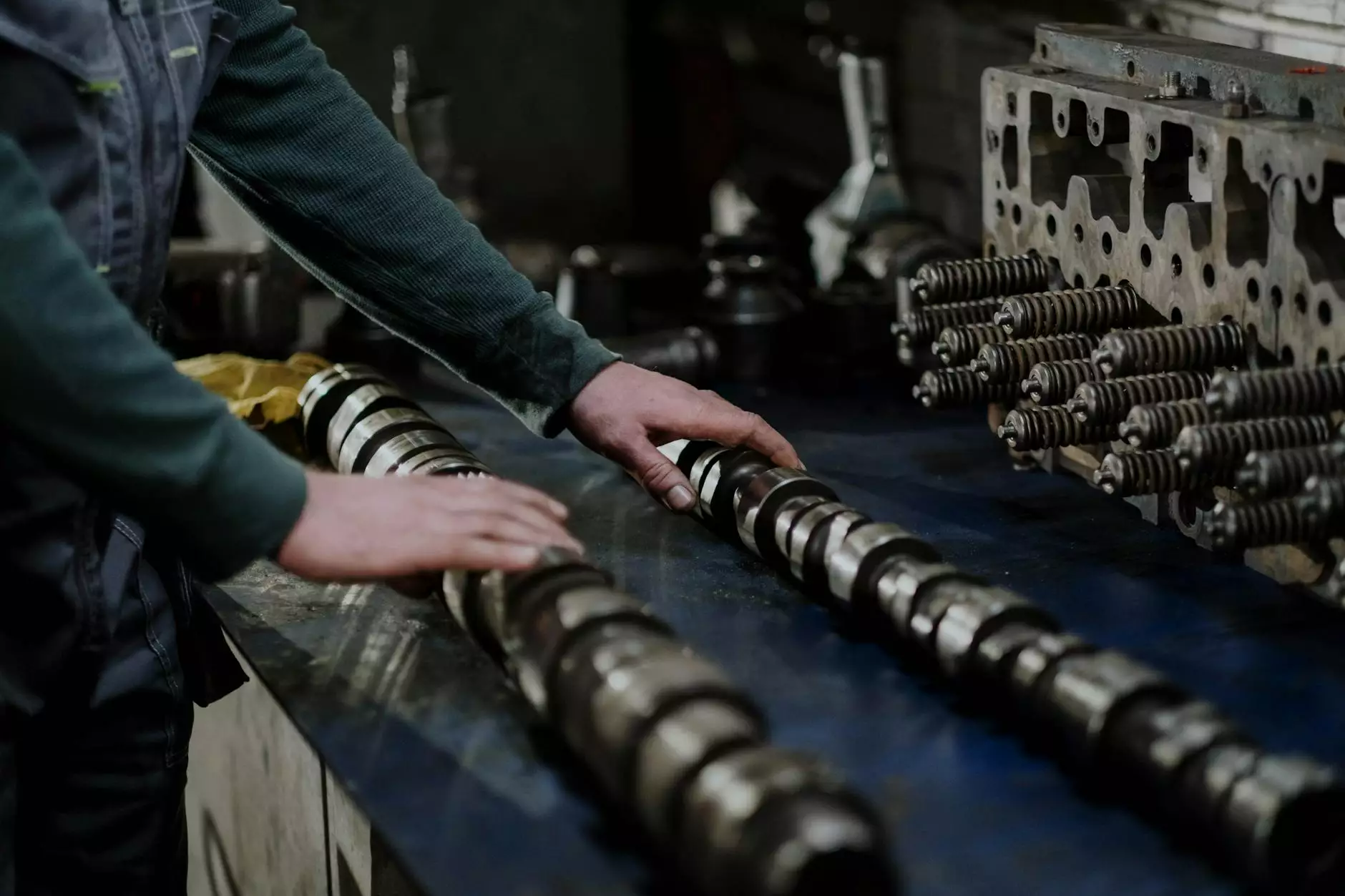

MTU parts are critical components used in MTU engines, which are known for their reliability and efficiency. These parts include everything from crankshafts, cylinder heads, and fuel injectors, to complete propulsion systems.

The Importance of Quality in MTU Parts

Quality is paramount when dealing with MTU parts. High-quality components ensure optimal engine performance, reduce maintenance costs, and extend the lifespan of the machinery. In this regard, the sourcing of these parts from reputable manufacturers in China plays a crucial role.

The Manufacturing Landscape in China

China has emerged as a global hub for manufacturing various mechanical components, including those essential for MTU engines. Landed on this massive industrial base, the operations are characterized by advanced technology, skilled labor, and competitive pricing.

Key Factors Driving MTU Parts Manufacturing in China

- Cost-Effective Labor: Access to a large workforce allows for reduced production costs.

- Technological Advancements: Modern manufacturing techniques ensure that products meet international standards.

- Export Capabilities: China’s robust supply chain facilitates the quick distribution of products globally.

Quality Assurance in Manufacturing MTU Parts

Ensuring the highest quality of MTU parts manufactured in China involves several layers of quality control. Manufacturers often adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system.

Stages of Quality Control

- Incoming Material Inspection: Raw materials are subjected to strict quality checks.

- In-Process Quality Checks: Regular inspections during manufacturing ensure that every aspect meets design specifications.

- Final Inspection: Finished parts undergo rigorous testing to confirm they meet MTU’s high standards.

The Role of MTU Parts in Diesel Engines and Generators

Diesel engines and generators are the backbone of various industries, powering everything from construction equipment to ships. The efficiency and reliability of these machines largely depend on the quality of components used, notably MTU parts.

Benefits of Using MTU Parts in Diesel Applications

- Enhanced Performance: MTU parts are engineered for maximum efficiency, contributing to lower fuel consumption.

- Reliability: These components are rigorously tested to withstand heavy loads and extreme conditions.

- Environmental Compliance: MTU parts are designed with emissions control in mind, adhering to strict environmental regulations.

Partnering with Engine Family: Your Source for MTU Parts in China

At Engine Family, we prioritize quality and customer satisfaction in our supply of MTU parts. As a leading diesel engine manufacturer and diesel generator supplier, we understand the demands of the industry and are committed to providing top-notch products to our clients.

Our Product Offerings

We offer an extensive range of MTU parts suitable for various applications. Our catalog includes:

- MTU Engine Components

- Propulsion Systems

- Fuel Injection Systems

- Alternators and Generators

- Cooling Systems

Why Choose Engine Family?

Engine Family stands out in the competitive landscape due to our dedication to quality, customer service, and expertise in MTU parts. Our supply chain is streamlined to ensure timely delivery, and our customer support team is always ready to assist with inquiries and technical support.

The Future of MTU Parts Production in China

As the global demand for reliable and efficient diesel engines grows, the manufacturing of MTU parts in China is expected to expand. Innovations in manufacturing technology, combined with a focus on sustainability, will likely shape the future landscape of this industry.

Emerging Trends in Manufacturing

- Automation: Increasing use of robotics and automated systems for higher efficiency.

- Sustainability Practices: Adoption of green manufacturing processes to minimize environmental impact.

- Advanced Materials: Utilizing new materials that enhance performance and reduce weight.

Conclusion

The demand for premium quality MTU parts in China continues to rise, driven by the industrial sector’s need for reliable and efficient diesel engines and generators. By collaborating with experienced suppliers like Engine Family, businesses can ensure they receive high-quality components that will enhance their operational capabilities.

As we move forward, understanding the complexities and advantages of sourcing MTU parts from China will be essential for companies looking to maintain a competitive edge in the diesel engine market.

mtu parts china