The Evolution and Advantage of UV DTF Ink in Modern Printing

In today's fast-paced business landscape, understanding and utilizing advanced printing technologies can significantly elevate a business's marketing and production capabilities. One remarkable advancement that has revolutionized printing in the industry is UV DTF ink. This technology not only enhances the quality of prints but also offers a versatile solution for various substrates. In this article, we will delve into the fundamentals of UV DTF ink, its applications, benefits, and how it can propel businesses to new heights.

Understanding UV DTF Printing

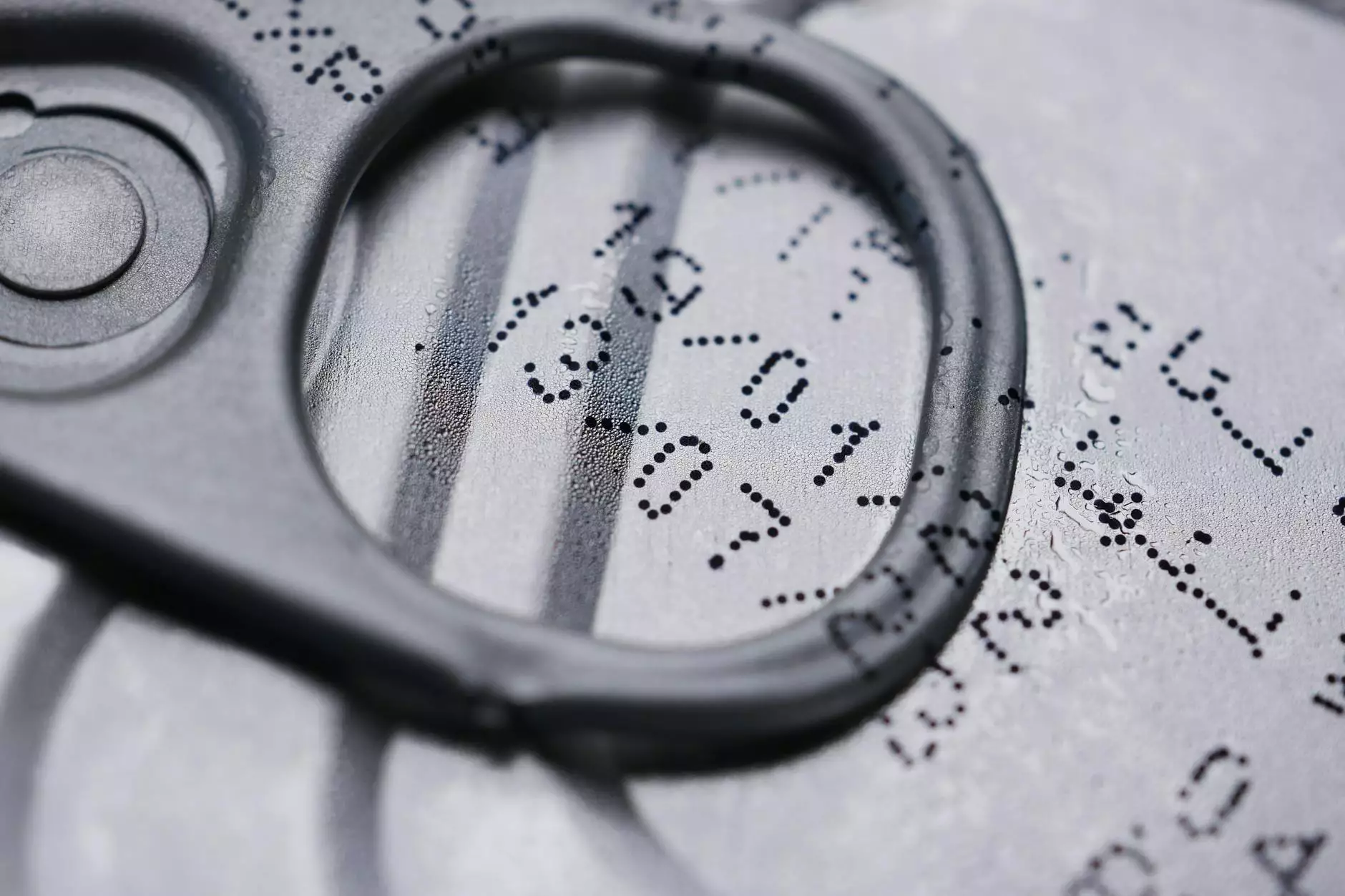

UV DTF, or Ultraviolet Direct to Film, is a printing method that utilizes significant advancements in technology to transfer high-quality images from a specially coated film onto a variety of substrates. This process stands out due to its unique use of UV light, which cures the ink almost instantly, ensuring a flawless finish that is both vibrant and durable.

The Printing Process

The process of UV DTF printing involves several crucial steps:

- Preparation: Select the film that will carry the design, ensuring it is compatible with the printer and ink.

- Design Setup: Create or choose a design to be printed, which can be done using graphics software that supports high-resolution images.

- Printing: The design is printed onto the film using the UV DTF ink, which is formulated to adhere well to the film surface.

- Heat Transfer: After printing, the film is applied to the desired substrate, such as fabric or hard surfaces, and heat is applied to transfer the ink.

- Curing: Finally, the UV light is used to cure the ink, resulting in a vibrant and long-lasting print.

Benefits of Using UV DTF Ink

The adoption of UV DTF ink provides a myriad of advantages:

1. Exceptional Print Quality

One of the most significant advantages of UV DTF ink is its ability to produce high-resolution prints with striking colors and details. The UV curing process enables the ink to dry almost instantly, preventing smudging and ensuring that the colors remain bold and vibrant without fading over time.

2. Versatility Across Substrates

UV DTF ink can be used on various materials, including textiles, plastics, ceramics, and metal. This versatility allows businesses to cater to a broader audience, offering customized products that meet diverse needs.

3. Durability and Longevity

Prints created with UV DTF ink exhibit exceptional durability and resistance to scratches, weathering, and UV exposure. This longevity means that products can withstand daily wear and remain visually appealing for extended periods, making them valuable for businesses in competitive markets.

4. Quick Turnaround Times

Thanks to the rapid curing process associated with UV DTF ink, businesses can significantly reduce turnaround times for orders. This capability is critical in industries where demand can fluctuate rapidly, allowing businesses to respond promptly to customer needs.

Applications of UV DTF Ink

The versatility of UV DTF ink opens up a world of possibilities in various sectors:

1. Textile and Fashion Industry

In the textile industry, UV DTF ink is ideal for customizing apparel and accessories. From vibrant t-shirt designs to intricate patterns on bags, this printing technique provides fashion brands with the ability to produce unique and customizable products that stand out in a crowded marketplace.

2. Promotional Products

Businesses can use UV DTF ink to create personalized promotional items such as mugs, phone cases, and pens. Customization enhances brand recognition and creates memorable marketing materials that can leave a lasting impression on customers.

3. Signage and Display

UV DTF ink is perfectly suited for creating signage and display materials. The prints produced are not only eye-catching but also weather-resistant, making them ideal for both indoor and outdoor use. Businesses can promote their brand effectively using stunning visuals that are designed to last.

4. Art and Decor

Artists and interior designers can leverage UV DTF ink to produce high-quality prints on canvases, plaques, and wall art. The ability to reproduce intricate artwork accurately makes this method an excellent choice for custom art pieces and decorative items.

Getting Started with UV DTF Ink

For businesses keen on integrating UV DTF ink into their operations, it’s essential to follow some guidelines:

1. Choose the Right Equipment

Investing in a quality UV DTF printer that suits your production needs is crucial. Assess your expected volume, budget, and features to make an informed decision.

2. Source Quality Materials

Ensure that you use high-quality films, inks, and substrates. The quality of materials will directly impact the final print quality.

3. Train Your Team

Proper training is essential to maximize the potential of UV DTF ink. Ensure your team is familiar with operating the equipment, handling materials, and understanding the printing process.

4. Create Unique Designs

With the technical aspect in place, focus on developing innovative designs that will captivate your target market. Unique and creative content will enhance the overall value of your products.

Conclusion

In conclusion, the integration of UV DTF ink into your printing processes can act as a game changer for your business. With its unparalleled print quality, versatility, and speed, UV DTF printing opens new avenues for creativity and production efficiency. Whether you're in the fashion industry, engaged in promotional products, or looking to enhance signage and art, UV DTF ink provides a modern solution that is both effective and aesthetically pleasing. By adopting this innovative technology, businesses can not only improve their product offerings but also gain a competitive edge in the ever-evolving market. Start exploring the possibilities with UV DTF ink today, and watch your business thrive in the realm of modern printing.